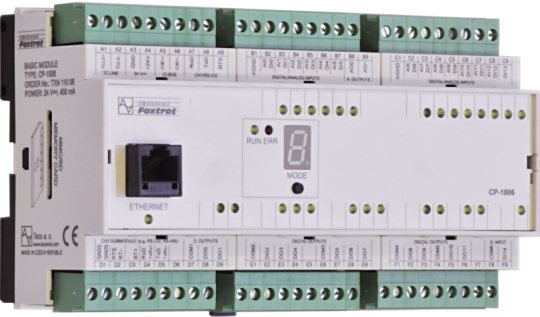

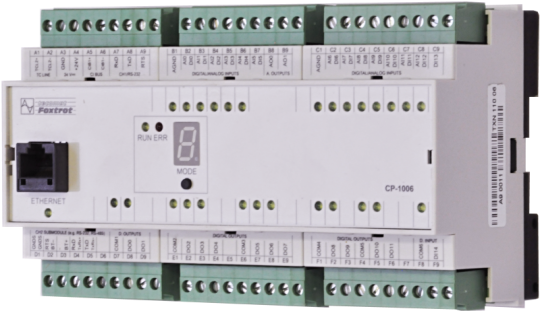

CP-1006TXN 110 06

CP-1006, CPU, ETH100/10, 1xRS232, 1xSCH, 13xAI/DI, 1xHSC, 1x DI/230V, 2xAO, 10xRO, 2xSSR, 1xCIB

| DI | 1x DI/HSC 1x DI 230 VAC |

|---|---|

| DI/AI | 13x AI/DI |

| DO | 10x RO 2x SSR |

| AI | |

| AO | 2x AO |

| COM | 1x ETH 1x RS-232 1-3x Serial Channel (1x free slot) 1x TCL2 1x CIB |

| SENSOR |

The basic module CP-1006 is from the range of basic modules (ZM) of modular programmable controllers of the Foxtrot series compatible with the harmonized standard ČSN EN 61131.. The individual ZMs differ in the number or type of inputs and outputs and the indication and control elements. The basic module CP-1006 is equipped with:

The basic module CP-1006 is equipped with a central unit (CPU) series K, which is designed for applications with performance requirements. Includes backed up CMOS RAM for user programs, data, tables, user registers and DataBox, Flash memory for user program backup, MMC / SD / SDHC memory card slot, real time circuit, Ethernet interface, two serial channels (one with fixed interface RS-232, the other with a position for optional submodules), one communication channel with a CIB interface for connecting external peripherals and a TCL2 system interface designed for connecting expansion modules that increase the number of I / O systems.

- 13 universal inputs, each can be used either as a 24 V binary input or as an analog input

- 1 quick input with counter function

- 1 input for monitoring the presence of mains voltage at the level of 230V.

- 10 relay outputs and

- 2 SSR semiconductor outputs.

- 2 analog outputs

The basic module CP-1006 is equipped with a central unit (CPU) series K, which is designed for applications with performance requirements. Includes backed up CMOS RAM for user programs, data, tables, user registers and DataBox, Flash memory for user program backup, MMC / SD / SDHC memory card slot, real time circuit, Ethernet interface, two serial channels (one with fixed interface RS-232, the other with a position for optional submodules), one communication channel with a CIB interface for connecting external peripherals and a TCL2 system interface designed for connecting expansion modules that increase the number of I / O systems.

| Order num. | TXN 110 06 |

|---|---|

| Teco code | TXN 110 06 |

| Categories | Foxtrot 1 - Basic modules |

| Tags | Sales and production discontinued |

| System parameters of the central unit | |

|---|---|

| Row of central unit | K |

| User program memory | 192 + 64 kB |

| Memory for user variables / including RETAIN variables | 64 kB/32 kB |

| Instruction length | 2 ÷ 10 bytes |

| Backup of program source code in PLC | Yes, in program backup memory (EEPROM) |

| On-line program change in PLC | Yes, including I / O configuration change |

| Memory for project archiving - internal | 2 MB |

| DataBox - additional internal data memory | 512 kB |

| Optional memory card slot | SD - Card Slot |

| Cycle time per 1k of logic instructions | 0,2 ms |

| Development environment | Mosaic |

| Programming languages | ST, IL, LD, FBD, SFC, CFC |

| RTC - Real time circuit | No |

| RAM and RTC backup 1) without / with backup battery | type. 500 hr / typ. 20,000 hours |

| Integrated Web server | Yes |

| Integrated Datalogger | Yes |

| Access to PLC variables via web API | Yes |

| Notice | 1) Applies to the basic module without power supply, the backup circuits are disconnected when the power supply is switched on 2) The serial interface CH1 is permanently equipped with an RS-485 interface. The serial interface type CH2 to CH4 is selectable via interchangeable submodules |

| COM - Communication - IP/Ethernet | |

| Ethernet 10/100 Mb (ETHx) | 1 |

| Available system modes on ETH and WLAN | UNI, PC, PLC, PLD |

| TCP / IP protocol | Yes |

| UDP protocol | No |

| HTTP protocol | No |

| WebSocket protocol | No |

| Protocol MODBUS/TCP | No |

| SMTP protocol | No |

| IEC 60870-5-104 protocol | No |

| REST API | No |

| COM - Serial channels | |

| max. number of optional serial channels in the basic module | 4 |

| max. number of expanding serial channels on the TCL2 bus | 6 |

| Number of internal RS-232 serial channels | 1 |

| Available system modes on CH5-10 | UNI, CSJ (CAN) |

| Modbus RTU / ASCII master protocol | No |

| Modbus protocol RTU/ASCII slave | No |

| Profibus DP master protocol (<180 kbit/s) | No |

| COM - System buses | |

| TCL2 - system I/O bus | 1x TCL2 master |

| TCL2 - Range of one branch of the system I/O bus | 10 I / O modules + 4 operator panels + 6 serial channels |

| The communication rate of the system I / O bus | 345 kbps |

| System I / O bus terminating resistor | 120 Ω |

| CIB - Common Installation Bus (R): Installation I/O bus | 1x CIB master (100 mA) |

| CIB - Address range of one branch of the installation bus | 32 CFox I/O modules |

| DI - Parameters of binary inputs DC (group A) | |

| Common wire | GND - module ground |

| Input type | Type 1 (IEC) |

| Galvanic isolation of inputs from internal/peripheral circuits | No |

| Diagnostics | indication of energized input by LED on module panel |

| Input voltage for log. 0 | 0 V DC; -5 V DC min.; +5 V DC max. |

| Input voltage for log. 1 | 24 V DC; 15 V DC min.; 30 V DC max. |

| Input current at log. 1 (typ.) | -1,7 mA |

| Delay from log. 0 to log. 1 | 5 μs |

| Delay from log. 1 to log. 0 | 5 μs |

| The minimum width of the captured pulse | 50 μs |

| Notice | Note that GND terminals in 24 V DC and DIGITAL / SPECIAL INPUTS they are connected inside the system. It is not desirable to connect the GND terminal in the DIGITAL / SPECIAL INPUTS with negative pole power supply system also inputs because it would over the second GND terminal closed the loop and thereby potentially induced interfering signals. |

| DI - Parameters of binary AC inputs | |

| Total number of binary AC inputs | 1 |

| Number of groups of AC inputs | 1 |

| Number of AC inputs in group | 1 |

| Organization of binary inputs into groups | DI14 |

| Input type | 230 V AC |

| Galvanic isolation of internal circuits | Yes |

| Input voltage for log. 0 | 0 V AC min., 120 V AC max. |

| Input voltage for log. 1 | 230 V AC typ., 200 V AC min., 250 V AC max. |

| Input current at log. 1 (typ.) | 5 mA typ. |

| Delay from log. 0 to log. 1 | 10 ms |

| Delay from log. 1 to log. 0 | 10 ms |

| HSC - Special functions of binary inputs / counters | |

| Unidirectional counter (UP) | 2x (DI0); (DI2) |

| Two unidirectional counters (UP / UPB) | 2x (DI0/DI2); (DI2/DI3) |

| Bidirectional counter (UP/DOWN) | 2x (DI0/DI1); (DI2/DI3) |

| Counter with direction control (CLK/DIR) | 2x (DI0/DI1); (DI2/DI3) |

| Bi-directional counter with reset and intercept (UP / DOWN / CLR / CAP) | 1x (DI0/DI1/DI2/DI3) |

| Counter with direction control with reset and latch (CLK / DIR / CLR / CAP) | 1x (DI0/DI1/DI2/DI3) |

| IRC Basic (V/G) | 2x (DI0/DI1); (DI2/DI3) |

| IRC with Zero and Capture (V / G / NI / MD) | 1x (DI0/DI1/DI2/DI3) |

| Measure the pulse length | 4x (DI0,DI1, DI2, DI3) |

| Period measurement | 4x (DI0,DI1, DI2, DI3) |

| DO - Parameters of SSR (solid state relay) outputs (group A) | |

| Max. current through COM terminal | 2A max. |

| Output type | triac with switching at 0/PWM |

| Galvanic separation of the output | Yes |

| Diagnostics | signaling of excited output by LED diode |

| Switching voltage (V) | min. 20VAC, max. 260VAC |

| Switching current (A) | max. 1A; min. 5mA |

| Internal protection, output treatment | No |

| Short circuit protection | No |

| Overload protection | no |

| Treatment of inductive load | external - RC element, varistor |

| Insulation voltage between outputs and internal circuits | 3750 V AC |

| Insulation voltage between groups of outputs | 3750 V AC |

| RO - Parameters of binary relay outputs (group A) | |

| Parameters valid for the terminals | DO0-DO5 |

| Number of relay outputs | 6 |

| Number of output groups | 2 |

| Number of outputs in group | 3 |

| Diagnose | Alarm signaling on panel module |

| Switching current | 3 A max., 100 mA min. |

| Switching voltage | 250 V AC max., 5 V AC min., 30V DC max. |

| Short-term output overload - inrush | 4 A max. |

| Current through common clamp | 10 A max. |

| Contact closing time | typ. 10 ms |

| Contact opening time | typ. 4 ms |

| Limit values of switched resistive load | max. 3A at 30 V DC or 230 V AC |

| Switching inductive load limits DC13 | max. 3 A at 30 V DC |

| Switching inductive load limits AC15 | max. 3 A at 230 V AC |

| Switching frequency without load | max. 300 switching / min. |

| Switching frequency with rated load | max. 20 switching / min. |

| Mechanical life | min. 5,000,000 cycles |

| Electrical life at maximum resistive load | min. 100,000 cycles |

| Electrical life at maximum load inductive DC13 | min. 100,000 cycles |

| Electrical life at maximum load inductive AC15 | min. 100,000 cycles |

| Short-circuit protection | No |

| Treatment of inductive load | External RC element, varistor (AC), diode (DC) |

| Insulation voltage between outputs and internal circuits | 3750 V AC |

| Isolation voltage between groups of outputs to each other | 3750 V AC |

| AI - Organization of analog inputs | |

| Total number of analog inputs | 4 |

| Number of inputs per group | 4 |

| Number of analog input groups | 1 |

| Organization of analog inputs into groups | 4x (DI4/AI0-DI7/AI3) |

| Input type | With common clamp |

| Common wire | Minus |

| Galvanic separation from internal circuits | No |

| Diagnostics | overload signaling in status word |

| Converter type | Approximation |

| conversion time | 20 μs |

| Operating modes | periodic input sensing |

| AI - Analog Input Ranges (Group A) | |

| Voltage | 0 to 10 V / 2,579 mV |

| Voltage input error - repeatability under steady state conditions | 0.05% of full scale |

| Permissible continuous overload - voltage input | -20 V to +30 V |

| Open input detection | No |

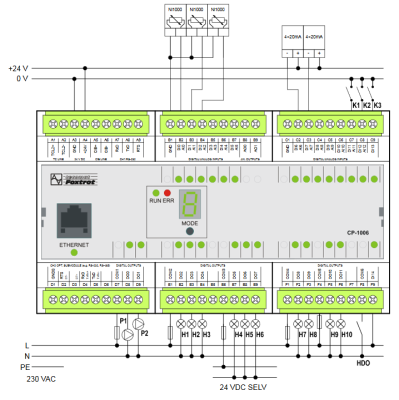

| Power supply | |

| Nominal supply voltage (V) | 24 V DC |

| Supply voltage, tolerances | 24 V DC, +25%, -15%, SELV |

| Supply voltage when backing up with an external battery | 27 V DC, +10%, –15%, SELV |

| Typical power input | 8 W |

| Maximum power input | 10 W |

| Module thermal/power loss | 7 W |

| Maximum current consumption (mA) | 500 mA |

| Galvanic separation of power supply from internal circuits | No |

| Internal protection | Yes, PTC reversible fuse |

| Description of power supply | Difference between typical and maximum power input is given by possible load of CIB buses and number of switched outputs and CPU load |

| CIB branch power supply - parameters of the built-in master | 1x 100 mA/ 24 V DC |

| Size and weight | |

| Weight approx. | 300 g |

| Product dimensions (width x height x depth) | 158 x 90 x 58 mm |

| Module width in multiples of M (17.5 mm) | 9M |

| Module width | 158 mm |

| Module height | 90 mm |

| Module depth | 58 mm |

| Product dimensions (width x height x depth) | 158 x 90 x 58 mm |

| Operating conditions, product standards | |

| Product standard | ČSN EN 61131-2: 2005 (idt IEC61131-2: 2003) - Programmable control units |

| Protection class of electrical object | II, according to ČSN EN 61140: 2003 (idt IEC 61140: 2001) |

| IP rating (Ingress Protection) according to ČSN EN 60529: 1993 (idt IEC 529: 1989) | IP20 |

| Operating areas | Normal, acc. ČSN 33 2000-1 ed.2: 2009 (mod IEC 60354-1:2005) |

| Degree of pollution | 1, according to ČSN EN 60664-1: 2004 (mod IEC 60664-1: 1992) |

| Overvoltage category installation | II, acc. ČSN EN 60664-1:2004 (mod IEC 606641:1992) |

| Type of device | Module on DIN rail |

| Working position | Vertical |

| Type of operation (operating frequency) | Continuous |

| Ambient operating temperatures | -20 °C to + 55 °C |

| Operating temperature maximum (° C) | +55°C |

| Operating temperature minimum (° C) | -20°C |

| Operating relative humidity | from 10 % up to 95 % without condensation |

| Operating atmospheric pressure | min. 70 kPa (<3,000 m above sea level) |

| Storage temperatures | –25 °C to +70 °C |

| Electromagnetic compatibility, Mechanical endurance | |

| Electromagnetic compatibility / Emission | A, according to EN 55022: 1999 (mod CISPR22: 1997) |

| Emmisions - note | In premises where the use of radio and television receivers can be expected to be used a distance of 10 m from these devices may cause radio interference. In such a case, the user may be required to take appropriate action. |

| Electromagnetic compatibility / Immunity | min. as required by EN 61131-2: 2007 |

| Sinusoidal vibration endurance | 10 Hz to 57 Hz, amplitude 0,075 mm, 57 Hz to 150 Hz, acceleration 1 G (Fc test according to EN 60068-2-6: 1997 (idt IEC 68-2-6: 1995), 10 cycles per axis.) |

| Packaginng, transportation, storage | |

| Description | The module is packed in a paper box according to the internal packing instructions. The package includes the following documentation. The outer packaging is carried out according to the scope of the order and the method of transport to the transport packaging bearing the transport labels and other particulars necessary for the transport. Transport from the manufacturer is carried out in the manner agreed upon when ordering. Product transport the customer's own means must be carried out by covered means of transport, in the specified position label on the packaging. The box must be stowed so as to prevent spontaneous movement a damage to the outer packaging. The product must not be exposed to direct weathering during transport and storage influences. Transport is allowed at temperatures from -25 ° C to +70 ° C, relative humidity 10% up to 95% (non-condensing) and a minimum atmospheric pressure of more than 70 kPa. The product may only be stored in clean rooms |

| Installation | |

| Assembly description | Switchboard mounting |

| Assembly description | The basic module is mounted vertically on the U-rail ČSN EN 50022. Installation of the assembly (basic module and peripheral modules, if any) is carried out according to TXV 004 10. |

| Attention! | The device may contain parts with dangerous voltages, covers being removed, or cabling manipulated, or disconnect the appropriate circuits or turn off the power !. |

| Exchangeable submodules | The optional MR-01xx submodules with serial channel 2 interface are mounted on the center plate in the CP-10x0 basic module to the position indicated in Fig. 7.1. To add or replace a submodule with a serial channel interface, release the latches on |

| Exchangeable submodules | The optional MR-01xx serial interface submodules are fitted to the CP-1004 basic module on the center plate to the position indicated in Fig. 7.1. If necessary, the installation or replacement of a submodule with a serial channel interface is required Use a screwdriver to release the latches on the bottom of the housing. After removing the lower part of the case, remove it the board assembly from the rest of the housing (by gently pressing the inner board assembly downward on the Slide the Ethernet connector down). After removing the top plate with indication and connector The Ethernet interface is a replaceable submodule accessible. After installing the submodule boards carefully insert into each other - be careful not to bend the tips and the following incorrect insertion. Then assembled Carefully slide the plate assembly into the cover. Pay attention to the risk of bending the LEDs and correct alignment button and ETHERNET connector. After insertion into the cover snap the bottom of the module. |

| Connection | |

| Connection of power and system communication | connector with 2.5 mm2 screw terminal |

| Connection of inputs / outputs | connector with screw terminal 2.5 mm2 |

| Ethernet | RJ-45 |

| Serial channels | screw-type connector 9x 2.5 mm2 |

| Module operation | |

| Module configuration | The module is operated, set up and diagnosed from the Mosaic development environment. |

| Commissioning | The module is ready for operation after connection of the supply voltage. The module panel is available MODE button to display the currently set Ethernet IP address. Parameters of all interfaces are set in the Mosaic programming environment. The exact setting procedure is shown in TXV 004 documentation 10. Other activities (programming, application debugging, etc.) are performed in the MOSAIC development environment. |

| Module diagnostics | The basic diagnostic system of the module is a part of its standard software. It operates from module power on and operates independently of the user. Diagnostic error the status of the module and the connected peripheral modules of the assembly are indicated on the module display and are available for processing by the master system. For more information see TXV 004 10. |

| Maintenance | |

| Description | The module does not require any maintenance under general installation conditions. The operations in which a part of the module has to be dismantled must always be carried out with the supply voltage disconnected. |

| Warning | Since the module contains semiconductor components, it is necessary to observe the rules for working with electrostatically sensitive components when handling the removed cover. It is not allowed to touch the printed circuits directly without protective measures. |

| Additional backup battery - maintenance |

|

| Warranty | |

| Generally | Warranty and complaint conditions are governed by the Terms and Conditions of Teco a.s. |

| Warning |

|

HW documentation

CP-1006 Basic documentation

400.63 kB, (CS, EN)

User manuals

Foxtrot1 - User's Guide, cze, , TXV00410_01

3.40 MB

Foxtrot1 - User Manual (en), TXV00410_02

4.30 MB

Files for designers

CP-1006

485.75 kB

CP-1006

104.64 kB

- CP-1006 - The CP-1006 I/O layout (inputs, outputs, power supply, communication interfaces) is identical with the CP-1016 module. The front panel is different: instead of LED indicators and a small seven-segment indicator there is a larger display with 4...

- Power dissipation of modules for calculation of switchboard heating - ...S232, 1xSCH, 6xAI/DI, 2xAO, 6xRO 230 V/ 3A, 1xCIB CP-1005 5,0 W TXN 110 06 CP-1006, CPU, ETH100/10, 1xRS232, 1xSCH, 13xAI/DI, 1xHSC, 1x DI/230V, 2xAO, 10xRO, 2xSSR, 1xCIB CP-1006 7,0...

- Control of the 24 V TORO valves for the irrigation systems - ...V series is shown in the following diagram. The wiring diagram illustrates the control of two valves by relay outputs of the CP-1006 basic module. The relay outputs of other modules can be used in the same way, e.g. the C-HM-0308M, etc. Thanks to the...

- CP-2007 - ...230 VAC input, especially suitable for HDO signal connection, see chapter 12.4.1 Snímání HDO signálu, základní modul CP-1006 The principles of protection and use for capacitive and inductive loads can be found in the chapter 13.7.1...

- Control of ILT motors manufactured by Somfy - ...-485 interface for connection to the control system. Fig. 1. An example of connecting the RS485 4ILT to the CH2 CP-1006...

- Measuring temperature – technology - ...they should be connected to the analogue inputs of CFox or RFox modules, or directly in the Foxtrot basic modules (e.g. the CP-1006 and CP-1008 ). The range of standard sensors can be found in the price list, and an overview of CFox modules suit...

- Metering the consumption of 1ph network, the 9901M and ED11.M electricity meter, measuring t - ...electricity meter. These electricity meters can be connected directly to the binary inputs of the basic modules CP-1008 and CP-1006 (see the example above), but they cannot be connected to the inputs with the 24 V (IB-1301), or the S0 inputs in Clas...

- Serial communication interfaces RS-232, RS-485, RS-422, CAN and others - The CP-1000 basic module (similarly to other Foxtrot basic modules, e.g. CP-1006) is always fitted with the RS-232 communication interface terminated on the CH1 channel; there is also an option to fit replaceable submodules to the channel CH2, wher...

- Measuring air velocity in ducts, the sensor PFLV12 - ...PG9/8mm Fig. 1. An example of wiring the PFLV12 sensor with current output to the CP-1006 module...

- Surge protection of the RS-485 (RS-232) communication interface - ...rge protection Fig. 2. An example of connecting surge protection of the RS-485 communication interface in CP-1006 Tab. 1. Technical parameters of SPDs BDM-006, BDM-012 and DM-006, DM-012 (SALTEK)...

- Foxtrot basic module power supply - ...CP-1005, CP-1015 8 W 4 W CP-1006, CP-1016 10 W 6 W CP-1008, CP-1018...

- CP-1000, CP-1001 - ...em includes solar water heating, heat sources control, charging the storage tanks, etc., it is advantageous to use the basic CP-1006 or CP-1008 modules, which have a higher number of inputs for connecting temperature sensors, outputs for continuous s...

- CP-1016 - ...for connecting ripple control signal, for an example of connection see Chapter 12.4.1 Scanning ripple signal, basic module CP-1006 . For principles of protection and usage for capacitive and inductive loads, see Ch...

- Internal CIB master at the CP-10xx - ...CP-1005, CP-1015 100 mA 1 A (module C-BS-0001M ) CP-1006, CP-1016 100 mA 1 A (module C-BS-0001M )...

- Decoupling power supply to CIB – the C-BS-0001M decoupling module - ...he CIB power circuitry of the basic modules fitted with a CIB power supply circuit only with a limited output (e.g. CP-1004, CP-1006), or for older versions of the Foxtrot basic modules, which had no CIB supply circuits installed. Maximum load of...

- First generation Tecomat Foxtrot PLC - ..., Provedení: DIN-RAIL, Interface: Multi, Bus: TC700, Input: true, Output: true, Analog: true, Binary: true ] CP-1006 CP-1006-Základní modul Foxtrot [ AO: 2, DI: 2, DO: 12, Typ: PLC-Foxtrot, Výrobce: Teco, Provedení: DIN-RAIL,...

- The FOXTROT basic modules - The CP-10xx analogue inputs, ranges, basic information The analogue inputs in basic modules make it possible to connect a number of sensors and measured signals. Each CP-10xx variant is fitted with various numbers of inputs with different para...

- Heat measurement, produced and consumed heat of DHW and CH (eg heat pump) - To measure heat (produced or consumed) we use a flow meter, eg TA-E/20 with a pulse output, which we connect to the pulse inputs of the C-AM-0600I , modules, or to the binary potential-free inputs of the basic module CP-10x8 , CP-10x6 . T...

- Measurement of production and consumption of el. energy, 3f fast measurement, electricity me - For fast and accurate measurement of 3f network (measurement of phase voltages, currents, active and reactive powers, power factors, THD voltages and currents and frequencies in the LV network, etc.), in the range of rated currents from 15 A to 150...

- Measurement of DC voltage, current and power (PV, etc.) - In applications with photovoltaic panels or a small wind turbine, we sometimes need to measure the DC network - DC voltage, current and power. For measuring voltage up to 400 VDC, current up to 1000 ADC we can use DC electricity meter VMU-E. The bas...

- The SMM33 module for measuring and analysis of 3ph network - In order to provide a detailed analysis of a 3ph network (measuring and monitoring the line and phase voltages, currents, active and reactive power, the power factor, THD voltages and currents and frequencies in the low-voltage network, etc.), you...

- Connecting an electricity meter via the TXN 149 01 optical head - The TXN 149 01 optical interface probe (also called an optical head) is designed to read data and to communicate with the electricity meter, the ripple control receiver and other devices. The probe converts optical signals into signals of the serial...

- Recurring FC_FILEWRITE error - Hello, once every few months a CP-1006 unit stops working with an E-95-00-00ff6a (run time exceeded) error code and shows the attached popup window when I prompt the "About error..." button. It seems it has trouble with the built-in file writing fu...

- Technical documentation - Hello, I would like to request technical documentation regarding the basic module CP-1006, manual/design guide/other. Thank you in advance. Kind regards, Ana Pinto

- Technical documentation - ...al for them was only in Czech language. Similar system is CP-1005 and its manual is here (English version). The manual for CP-1006 in the Czech language version is here I am very sorry I can't help you immediately....