C-HC-0201F-ETXN 133 48.01

C-HC-0201F-E; CIB head, 2x AI/DI RTD/contact, 1x proportional valve control, mounting set M30x1.5

| DI | |

|---|---|

| DI/AI | 2x DI/AI |

| DO | |

| AI | |

| AO | |

| COM | 2x CIB slave |

| SENSOR | Internal temperature sensor Built-in valve actuator |

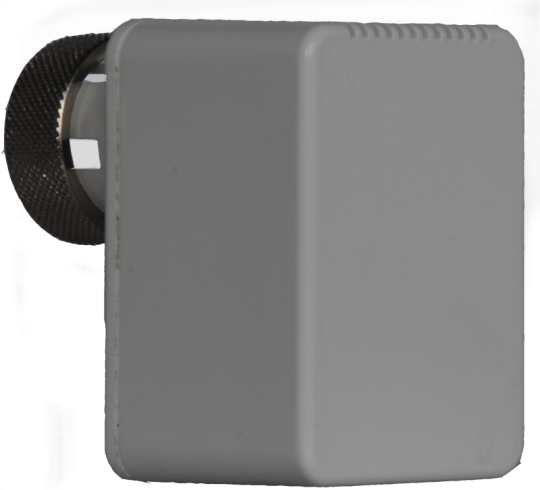

| Picture | Variant | Variant description |

|---|---|---|

|

C-HC-0201F-E |

C-HC-0201F-E is a module connected to the CIB Common Instalation Bus ® designed for proportional control of radiator

central heating valves with M30x1.5 fittings. It has integrated 2 universal inputs 2x AI / DI.

central heating valves with M30x1.5 fittings. It has integrated 2 universal inputs 2x AI / DI.

| Order num. | TXN 133 48.01 |

|---|---|

| Teco code | TXN 133 48.01 |

| Categories | CFox - Interior modules |

| Tags | - |

| COM - System buses | |

|---|---|

| CIB - Common Installation Bus (R): Installation I/O bus | 1x CIB slave |

| DI - Parameters of binary inputs DC (group A) | |

| Number of inputs in group | 2 |

| Common wire | COM |

| Combined input type | DI/AI Active, for sensing potential-free contacts and measuring resistance sensors |

| Galvanic isolation of inputs from internal/peripheral circuits | No |

| Diagnostics | signaling of excited input in Mosaic |

| Input voltage | 3.3 V from internal source |

| Input current at log. 1 (typ.) | 3,3 mA |

| Delay from log. 0 to log. 1 | 10 ms |

| Delay from log. 1 to log. 0 | 500 ms |

| The minimum width of the captured pulse | 10 ms |

| AI - Analog Input Ranges (Group A) | |

| Passive sensor | Pt1000, W100 = 1,385 (-90 to +320 °C) |

| Passive sensor | Pt1000, W100 = 1,391 (-90 to +320 °C) |

| Passive sensor | Ni1000, W100 = 1,500 (–60 to +200 ° C) |

| Passive sensor | Ni1000, W100 = 1.617 (-60 to +200 ° C) |

| Passive sensor | Resistance transmitter 0-160 kOhm |

| Passive sensor | KTY81-121; PTC thermistor (-55 to + 125 °C) |

| Passive sensor | NTC Thermistor 12k / 25 °C (-40 to + 125 °C) |

| Input impedance in signal range RTD | > 1 kΩ |

| Resistance measurement error - maximum error at 25 ° C | ± 2% of full scale |

| Resistance measurement error - temperature coefficient | ± 0,1% of full scale |

| Resistance measurement error - non-linearity | ± 0.2% of full scale |

| Resistance measurement error - repeatability at steady conditions | 0.5% of full scale |

| Detection of disconnected sensor | No |

| Parameter des Temperatursensors | |

| Temperature - Measurement range | -10 ÷ +50 °C |

| Temperature - Measurement error | <5% of range |

| Temperature - Settling time | 30 min. |

| Valve drive parameters | |

| Drive stroke - typical value | 1,5 mm |

| Drive stroke - maximum value | 2,5 mm |

| Valve drive speed | 0,05 mm/s |

| Adaptation of actuator with valve | automatic + manual |

| Flange type - thread | 1/2" |

| Automatic valve rotation | 30 days |

| Notice |

1) Typical stroke for most types of valves is approx. 1.5 mm. The exact stroke value can be set when configuring the module in the Mosaic environment. 2) Adaptation is performed automatically after switching on the supply voltage. Adaptation can be further started using manual control or from the user program. |

| Power supply | |

| Supply voltage, tolerances | 24/27 V DC from CIB bus |

| Power supply from CIB - typical current consumption (mA) | 5 mA |

| Power supply from CIB - maximum current consumption (mA) | 80 mA |

| Power supply from CIB - internal protection | No |

| Size and weight | |

| Weight approx. | 125 g |

| Product dimensions (width x height x depth) | 69 x 48 x 73 mm |

| Operating conditions, product standards | |

| Product standard | ČSN EN 60730-1 ed. 2:2001 (mod IEC 60730-1:1999) |

| Protection class of electrical object | I, according to ČSN EN 61140 ed.3: 2016 (idt IEC 61140:2016) |

| IP rating (Ingress Protection) according to ČSN EN 60529: 1993 (idt IEC 529: 1989) | IP10B |

| Operating areas | Normal, acc. ČSN 33 2000-1 ed.2: 2009 (mod IEC 60354-1:2005) |

| Degree of pollution | 1, according to ČSN EN 60664-1 ed.2:2008 ( idt IEC 60664-1:2007) |

| Overvoltage category installation | II, according to EN 60664-1 ed_2: 2008 (idt IEC 60641-1: 2007) |

| Working position | Any |

| Type of operation (operating frequency) | Continuous |

| Ambient operating temperatures | –10 ° C to +70 ° C |

| Operating relative humidity | from 10 % up to 95 % without condensation |

| Operating atmospheric pressure | min. 70 kPa (<3,000 m above sea level) |

| Storage temperatures | –25 °C to +70 °C |

| Electromagnetic compatibility, Mechanical endurance | |

| Electromagnetic compatibility / Emission | B, according to EN 55022: 1999 (mod CISPR22: 1997) |

| Packaginng, transportation, storage | |

| Description | Модуль упакован в антистатический пакет. Эта документация также является частью пакета. Внешняя упаковка осуществляется в соответствии с объемом заказа и способом транспортировки в транспортной упаковке, снабженной этикетками и другими данными, необходимыми для транспортировки. Продукт не должен подвергаться воздействию прямых погодных условий во время транспортировки и хранения. Соложение продукта разрешено только в чистых помещениях. без токопроводящей пыли, агрессивных газов и паров. Наиболее подходящая температура хранения - 20 ° C. |

| Installation | |

| Assembly description |

The C-HC-0201F-E module is mounted on the valve in any position by means of a flange. However, it is not recommended to mount the head to the valve from below, as water leaking from a leaking valve can damage the head. Installation of the assembly (basic module and possibly peripheral modules) is performed according to TXV 004 13. The figure shows an example of the C-HC-0201F-E module assembly. The C-HC-0201F-E module is mounted on the valve using a flange. A washer and insert are also inserted between the valve and the module. |

| Connection | |

| Connection of power and system communication | terminal block with spring terminal 1.5 mm2, push-in |

| Connection of inputs / outputs | terminal block with spring terminal 1.5 mm2, push-in |

| Module connection |

The combined module is implemented as a CIB bus module, which provides communication and power supply to the module. An example of module connection is shown in the following figure. The terminals for connecting the CIB bus are accessible after removing the head cover. In the mechanics of the module there are places for wire outlets (see Figure). According to the requirements of the application, it is possible to create openings for the passage of conductors in these places. |

| Function | |

| Automatic adaptation | The C-HC-0201F module can be connected to various types of valves. The valves have different dimensions and therefore different end positions. When the supply voltage of the module (CIB bus) is switched on, it automatically adapts to the connected valve. Ie. automatic finding of the position when the valve is completely closed (0%). From this reference position, the stroke of the valve actuator can then be controlled according to the set value (eg for a typical stroke of 1.5 mm ~ 100%). |

| Valve configuration | The module is equipped with an autoadaptation function that adapts the thermostatic head to the valve. For the correct function of the valve, it is necessary to configure 2 parameters, which can be set when configuring the module in the Mosaic development environment. The first parameter is the offset of the valve stroke, or the extent to which we will control the valve. The typical stroke size is 1.5 mm. You can adjust the stroke size by changing the parameter. The second parameter is the relief of the valve seal. During autoadaptation, the end position "valve closed" is found, from which we control the valve in the range 0-100%. However, this end position does not take into account the denting of the seal. It would happen that the valve would not react to small values of the set opening when opening. |

| Manual control |

For service interventions, the module is equipped with a "MAN" button. After pressing it and releasing it in an interval of 1.5 s after the required number of flashes of the green LED, one of the actions described in the following table can be called up. Number of flashes / Actions 2 flashes: Maximum valve opening (designed to make it easier to remove the module from the valve). The valve remains open until the adaptation is called or the supply voltage is restarted. 3 flashes: Adaptation of the valve module. |

| Frost protection | The internal temperature sensor is used for the frost protection function. If the measured temperature falls below 5 ° C, the actuator is set to the "fully open" position. |

| Module operation | |

| Commissioning | The module is operated, set and diagnosed from the MOSAIC programming environment or other parameterization software. The module is ready for operation after connecting the supply voltage and the CIB bus. The HW address is indicated on the label on the module. |

| Module diagnostics | The basic diagnostics is performed internally and the result is available in the relevant registers of the Mosaic environment. The module contains an indication LED for checking the status of inputs / outputs. By pressing the Manual Control button, the module can be switched to manual mode and the individual outputs can be controlled. |

| Maintenance | |

| Description | The module does not require any maintenance under general installation conditions. The operations in which a part of the module has to be dismantled must always be carried out with the supply voltage disconnected. |

| Notice | Because the module contains semiconductor components, it is necessary to follow the principles for working with electrostatic sensitive components when handling the removed cover. It is not allowed to directly touch the printed circuit boards without protective measures !!! |

| Warranty | |

| Generally | Warranty and complaint conditions are governed by the Terms and Conditions of Teco a.s. |

| Notice | You must meet all the conditions of this documentation before turning on the system. The system must not be put into service unless it has been verified and confirmed that the machinery meets the requirements of Directive 89/392 / EEC, in so far as it applies to it. Documentation subject to change. |

HW documentation

C-HC-0201F-E- Basic documentation

142.90 kB

User manuals

Peripheral module on CIB-Common Installation Bus(R) (cs), TXV00413_01

14.01 MB

Peripheral modules on the CIB Common Installation Bus(R) (en), TXV00413_02

13.94 MB, (EN, RU, DE, UA)

Files for designers

Foxtrot 2 - library of elements in DXF and DWG formats, v. 2025/08.

21.80 MB

Foxtrot 2 - element library for SchemataCAD, v. 2025/08.

6.96 MB

EC - Declaration of Conformity

Foxtrot 2 - EC Declaration of conformity (en)

590.59 kB, (EN, RU, DE, UA)

- The CFox motor drive C-HC-0201F-E - The C-HC-0201F-E motor drive can be used for continuous control of radiator valves. The drive is powered from CIB and it is fitted with 2 analogue inputs and internal temperature sensor. The drive is fitted with a quiet motor with a transmission;...

- Hot water heaters, panel radiators - .... For standard applications (hot water panel radiators) the following drives can be used: The CFox drive C-HC-0201F-E or the C-HC-0101F (in preparation) and if the wireless option is required, it is possible to use an RFo...

No data available.