C-EM-0300M, 3f electricity meterTXN 143 09

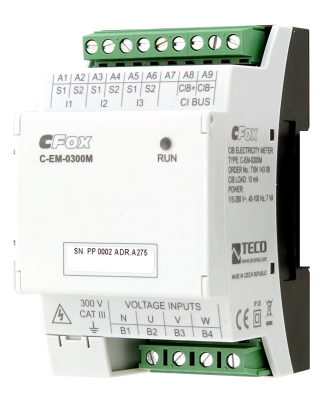

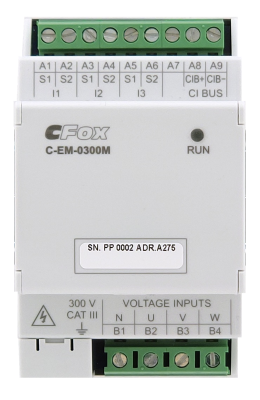

C-EM-0300M; CIB fast electricity meter/quality meter, power supply 230 V AC/DC, 3x U, 3x I - for current transformer x:333 mV

| DI | |

|---|---|

| DI/AI | |

| DO | |

| AI | 3x U (230 V AC) 3x I (333mV AC) |

| AO | |

| COM | 1x CIB slave |

| SENSOR |

| Picture | Variant | Variant description |

|---|---|---|

|

C-EM-0300M, 3f electricity meter |

Module of a 3-phase 4-quadrant fast electricity meter / quality meter providing all parameters of the consumed and supplied energy every 200 ms. The measurement is indirect, currents are sensed according to current transformers according to the required input range with a unified output of 333 mV. Data is transmitted via the two-wire CIB - Common Installation Bus®

| Order num. | TXN 143 09 |

|---|---|

| Teco code | TXN 143 09 |

| Categories | CFox - Modules on DIN rail, Electricity meters |

| Tags | - |

| COM - System buses | |

|---|---|

| CIB - Common Installation Bus (R): Installation I/O bus | 1x CIB slave |

| Measurement of supply network parameters - frequency | |

| Nominal frequency | 50/60 Hz |

| Frequency range | 42 - 70 Hz |

| Frequency measurement accuracy | ±20 mHz |

| Measurement of supply network parameters - voltage | |

| Rated voltage UNOM (UDIN) | 180–250VAC |

| Crest factor in UNOM | 2 |

| Measuring range, phase voltage (UL-N) | 8÷355 V AC |

| Measuring range, combined voltage (UL-L) | 14 ÷ 615 V AC |

| Voltage measurement accuracy | ± 0.05% of value or ± 0.1% of range |

| Temperature drift | ± 0.03% of value; ± 0.01% of range / 10 ºC |

| Measurement category | 300V CAT III |

| Input impedance | min. 6,12 MΩ |

| Input consumption | max. 0,05 VA |

| Permanent overload (UL-N) | 1355 V AC |

| Peak overload, for 1 s (UL-N) | 2140 V AC |

| Measurement of supply network parameters - currents | |

| Method for measuring current | indirect via current transformer |

| Nominal current of transformer Inom | Inom A AC => 333 mV AC |

| Crest factor at Inom | 1,8 |

| Measuring range | 0,003÷1,2×Inom |

| Current measurement accuracy | ± 0.1% of value or ± 0.01% of range |

| Input impedance | 39 kΩ |

| Input consumption | max. 5 μVA |

| Permanent overload | 2×Inom, 666 mV AC |

| Peak overload, for 1 s, repetition period min. 300 s | 10× INOM |

| Measurement of supply network parameters - other quantities | |

| Active power, measuring range (PNOM = UNOM × INOM×cosφ); [W, V, A] | limited by measured voltage and current ranges |

| Reactive power, measuring range (QNOM = UNOM × INOM×sinφ); [VA, V, A] | limited by measured voltage and current ranges |

| Reference conditions (A) |

• ambient temperature tA = 23 ± 2 ° C • U = 80–120% UNOM • I = 1–120% INOM • PF = 1 for active power acosφ • PF = 0 for reactive power |

| Accuracy of active or reactive power (A) | ± 0.5% of value or ± 0.01% of Pnom |

| Measurement accuracy PF and cos φ (A) | ±0,01 |

| Reference conditions (B) |

• ambient temperature tA = 23 ± 2 ° C • U = 80–120% UNOM • I = 2–120% INOM • PF≥0.5 for active power acosφ • PF≤0.87 for reactive power |

| Accuracy of active or reactive power (B) | ± 1% or ± 0.01% PNOM |

| Measurement accuracy PF and cos φ (B) | ±0,01 |

| Temperature drift performance | ± 0.05% of value or ± 0.02% PNOM / 10 ° C |

| Energy, measuring range | limited by measured voltage and current ranges |

| Accuracy of active energy measurement | class 1 (according to EN 62053-21) |

| Power supply | |

| Nominal supply voltage (V) | 230 V AC |

| Supply voltage, tolerances | 115-280 V AC, 115-380 V DC |

| Typical power input | 2 W |

| Module thermal/power loss | 3 W |

| Galvanic separation of power supply from internal circuits | No |

| Internal protection | No |

| Size and weight | |

| Weight approx. | 150 g |

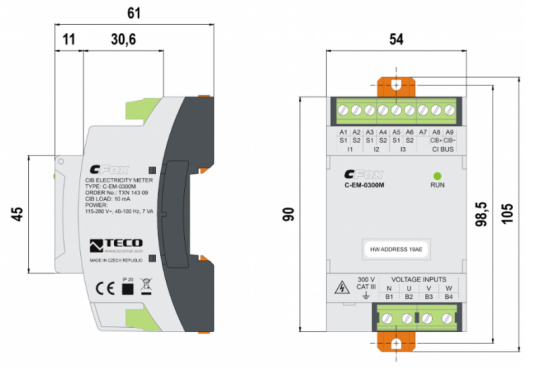

| Module width in multiples of M (17.5 mm) | 3M |

| Product dimensions (width x height x depth) | 54 × 90 × 61 mm |

| Operating conditions, product standards | |

| Product standard | ČSN EN 60730-1 ed.4 :2017 (EN 60730-1:2016) -Automatic electronic control device (for household and similar purposes) |

| Protection class of electrical object | II, according to ČSN EN 61140 ed.3: 2016 (idt IEC 61140:2016) |

| IP rating (Ingress Protection) according to ČSN EN 60529: 1993 (idt IEC 529: 1989) | IP20 |

| Operating areas | Normal, acc. ČSN 33 2000-1 ed.2: 2009 (mod IEC 60354-1:2005) |

| Degree of pollution | 2, according to ČSN EN 60664-1 ed.2: 2008 (idt IEC 60664-1: 2007) |

| Overvoltage category installation | III, according to EN 60664-1 ed_2: 2008 (idt IEC 60641-1: 2007) |

| Type of device | Module on DIN rail |

| Working position | Vertical |

| Type of operation (operating frequency) | Continuous |

| Ambient operating temperatures | -20 °C to + 55 °C |

| Operating relative humidity | from 10 % up to 95 % without condensation |

| Operating atmospheric pressure | min. 70 kPa (<3,000 m above sea level) |

| Storage temperatures | –25 °C to +70 °C |

| Electromagnetic compatibility, Mechanical endurance | |

| Electromagnetic compatibility / Emission | A, according to EN 55032 ed. 2: 2017 (idt CISPR 32: 2015) |

| Electromagnetic compatibility / Immunity | min. according to ČSN EN 60730-1 ed.3: 2012 |

| Sinusoidal vibration endurance | 10 Hz to 57 Hz, amplitude 0,075 mm, 57 Hz to 150 Hz, acceleration 1 G (Fc test according to EN 60068-2-6: 1997 (idt IEC 68-2-6: 1995), 10 cycles per axis.) |

| Packaginng, transportation, storage | |

| Description | The module is packed in a paper box. This documentation is also part of the package. The outer packaging with current transformers is carried out according to the scope of the order and the method of transport in a transport package provided with labels and other data necessary for transport. The product must not be exposed to direct weather conditions during transport and storage. The product may only be stored in clean rooms free of conductive dust, aggressive gases and vapors. The most suitable storage temperature is 20 ° C. |

| Installation | |

| Assembly description | Das Modul kann auf zwei Arten montiert werden: entweder durch Montage auf der 35 mm breiten U-Schiene des Instrumententrägers ČSN EN 60715 oder durch Verschrauben von zwei Schrauben an der Basis (nach dem Ausfahren der Befestigungsklammern an der Unterseite des Moduls beträgt der maximale Schraubendurchmesser 4 mm). Die Abmessungen des Moduls und der Abstand der Löcher für die Montage des Moduls an den Schrauben sind in Abb. 1 dargestellt. Am Ort der Installation des Geräts und seiner unmittelbaren Umgebung muss eine natürliche Luftzirkulation zugelassen werden. Weitere Informationen zur Installation finden Sie im CFox-, RFox- und Foxtrot-Konstruktionshandbuch, Bestellnummer: TXV 004 16. |

| Connection | |

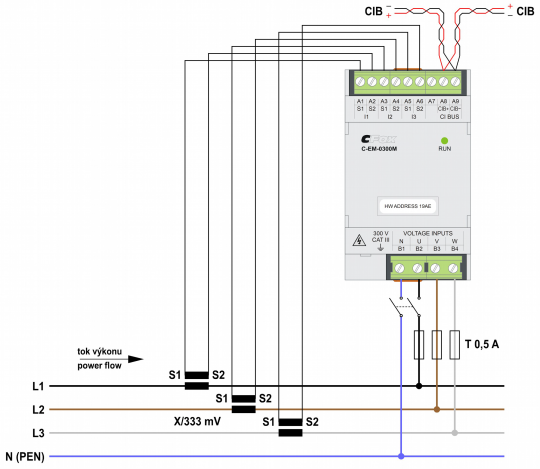

| Connection description | The module is connected with screw terminals. The measured voltages connect a suitable fuse element with characteristics according to the environment (eg fuse with a value of 0.5 A) to the terminals U, Va W, the middle conductor is connected to the common terminal N. Power supply of the module is realized via terminals U and N, therefore it is necessary that the terminal N is always connected to a suitable potential (in a delta connection or in an Aaron connection). The voltage measuring inputs are connected to the internal circuits via a high impedance. To connect the current inputs, it is necessary to use measuring current transformers with a secondary winding with a nominal value of 333 mVs corresponding to the measurement category / insulation voltage or to install the transformers on an insulated primary conductor with a corresponding insulation voltage. The secondary windings of the transformers are connected to terminals S1 and S2 of the current inputs I1, I2 and I3. All terminals S2 are galvanically connected to the same potential inside the module. If it is necessary to ground the secondary side of the measuring transformers, it is therefore necessary to connect terminals S2. The recommended conductor type for connecting the measured voltage and current is H07V – U (CY) cross section 0.5 mm2–2.5mm2. The CIB bus is connected to the CIB + and CIB– terminals. The number of modules on the CIB bus is limited by the maximum permitted bus current. The correct connection of the module, including the correct connection of current transformers, is illustrated in Fig. 2. |

| Connection of power and system communication | terminal block with screw terminal 2.5 mm2 |

| Connection of inputs / outputs | terminal block with screw terminal 2.5 mm2 |

| Module operation | |

| Commissioning |

The module is ready for operation after connecting the supply voltage and the CIB bus. It does not contain any controls and is operated, set up and diagnosed from the MOSAIC programming environment. The address is indicated on the label on the front panel. When initializing the module, the correct value of the primary current INOM of the respective current transformers (current range) must be entered. Note: CIB master CF-1140 / CF-1141 with FW version 2.0 and higher is required for correct module operation! Attention: When working with the module, it is necessary to observe all necessary measures to protect people and property from injury and damage by electric shock! The module must be operated by a person with the prescribed qualification for such an activity and this person must be thoroughly acquainted with the principles of working with the module. If the module is connected to parts that are under dangerous voltage, all necessary measures must be taken to protect users and equipment from electric shock. Workers installing and / or maintaining the equipment must be equipped with and use personal protective equipment and other safety equipment at work. If the module is used in a manner not specified by the manufacturer, the protection provided by the module may be reduced. Further information can be found in the manual Peripheral modules on the CIB bus, order no .: TXV 004 13.01. |

| Module diagnostics | The basic diagnostics are performed internally and the measurement results are available in the relevant registers of the Mosaic environment. The status of the module is indicated by the green RUN LED located on the front panel below the terminals for connecting the CIB bus. After connecting the CIB bus, the green RUN diode lights up and its light indicates the presence of the supply voltage on the CIB interface. After communication between the module and the central unit, the RUN LED flashes. This prepares the module for operation. |

| Maintenance | |

| Description | The module does not require any maintenance under general installation conditions. The operations in which a part of the module has to be dismantled must always be carried out with the supply voltage disconnected. |

| Notice | Because the module contains semiconductor components, it is necessary to follow the principles for working with electrostatic sensitive components when handling the removed cover. It is not allowed to directly touch the printed circuit boards without protective measures !!! |

| Warranty | |

| Generally | Warranty and complaint conditions are governed by the Terms and Conditions of Teco a.s. |

| Notice | You must meet all the conditions of this documentation before turning on the system. The system must not be put into service unless it has been verified and confirmed that the machinery meets the requirements of Directive 89/392 / EEC, in so far as it applies to it. Documentation subject to change. |

HW documentation

C-EM-0300M - Basic documentation

2.92 MB, (EN)

User manuals

Peripheral module on CIB-Common Installation Bus(R) (cs), TXV00413_01

14.01 MB

Peripheral modules on the CIB Common Installation Bus(R) (en), TXV00413_02

13.94 MB, (EN, RU, DE, UA)

Files for designers

Foxtrot 2 - library of elements in DXF and DWG formats, v. 2025/08.

21.80 MB

Foxtrot 2 - element library for SchemataCAD, v. 2025/08.

6.96 MB

EC - Declaration of Conformity

Foxtrot - EC Declaration of conformity

295.20 kB, (EN, RU, DE, UA)

- C-EM-0300M (R-EM-0300M-A) - measurement of production and consumption of el. energy, 3f fast - ...ure and also for automatic load control. For connection to the control system, it is available in a version with a CIB bus ( C-EM-0300M ) or an RFox2 wireless connection ( R-EM-0300M-A ). The device measures three voltages and three currents....

- Measurement of large currents with the C-EM-0300M electricity meter - Current sensors based on the Rogowski coil principle can be used to measure large currents, typically up to 6000 A AC. E.g. JRF MOI 333M-115 These sensors must be powered with a voltage of +5VDC, so th...

- Power dissipation of modules for calculation of switchboard heating - ...er KMB, 230 V, 3x measurement input U and I) R-EM-0300M-A 3,0 W TXN 143 09 C-EM-0300M (CIB 3-phase electricity meter KMB, 230 V, 3x measurement input U and I) C-EM-0300M 3,0 W...

- Openable transformer for current measurement with 333 mV output - Current transformers with a secondary output voltage of 333 mV use, for example, electricity meters C-EM-0300M and R-EM-0300M-A . It is not necessary to short-circuit this transformer during handling. The split core of the current transforme...

- Metering electrical energy - ...available directly on the CIB bus. We are currently preparing a simpler version of the CIB three-phase electricity meter C-EM-0300M and its wireless version R-EM-0300M-A. We have solutions with EMU and EMI modules for measuring consumptio...

- Antennas for RFox2 in version A, 868 MHz - Antenna 2JW0315-868-C675B Standard 868 MHz ISM antenna suitable for RFox2 modules equipped with an SMA connector for connecting an external antenna (eg modules C-RF-0001M-A , R-EM-0300M-A and others). Standards...

No data available.