CP-2090.11NSNNTXN 120 90.11NSNN

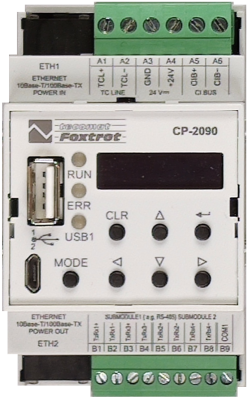

CP-2090, CPU/1core, 2xETH100/10, ---, 128kB databox, LCD-7mm, CH1-4, 1xCIB, 1x TCL2

| DI | |

|---|---|

| DI/AI | |

| DO | |

| AI | |

| AO | |

| COM | 2x ETH 10/100 4x Serial channel (2x free slot) 1x USB device 1x USB host 1x TCL2 master 1x CIB master |

| SENSOR |

| Picture | Variant | Variant description |

|---|---|---|

|

CP-2090.11NSNN | Databox: 128 kB Processor: 1 core, ARMv7 792 MHz Display: OLED display small 26 x 7 mm |

The CP-2090 is the smallest, second-generation Foxtrot base module. It only occupies the width of 3 modules on the DIN rail. It reaches this size due to the absence of any inputs / outputs.

The masters of both system expansion buses - TCL2 and CIB Common Installation Bus® - are a matter of course. It can therefore be extended in the same way as other basic modules.

CP-2090 is therefore suitable as a flexible freely programmable communication center, programmable converter of interfaces and protocols, data logger with its own web server,

with fast and high-capacity data storage up to 1 TB with file system, etc.

Except for the built-in LTE modem, which requires a minimum width of 6M modules, the basic module CP-2090 has all the attributes of the new generation of the central unit:

Communication capabilities of the basic module CP-2090:

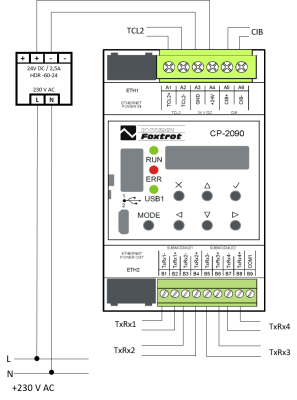

Power supply 24 V DC or via passive PoE - (power over Ethernet)

CP-2090 is equipped with a new powerful central unit (CPU series L) with memory

The masters of both system expansion buses - TCL2 and CIB Common Installation Bus® - are a matter of course. It can therefore be extended in the same way as other basic modules.

CP-2090 is therefore suitable as a flexible freely programmable communication center, programmable converter of interfaces and protocols, data logger with its own web server,

with fast and high-capacity data storage up to 1 TB with file system, etc.

Except for the built-in LTE modem, which requires a minimum width of 6M modules, the basic module CP-2090 has all the attributes of the new generation of the central unit:

Communication capabilities of the basic module CP-2090:

- 2x Ethernet interface 100 Mbit / s, each with up to 32 simultaneous connections (programming and general IP communication)

- USB micro (programming)

- USB A for Flas memory, WiFi adapter (client and AP - Access point) etc.

- Variant with built-in LTE modem for direct wireless connection to the Internet via a mobile network operator

- Slots for up to 4 optional serial interfaces RS-485, RS-232

Power supply 24 V DC or via passive PoE - (power over Ethernet)

CP-2090 is equipped with a new powerful central unit (CPU series L) with memory

- 1 MB for user program,

- 128 MB internal disk for storing files with parallel access from the LAN as a network disk,

- 16MB fast RAM disk

- microSD card slot up to 1 TB

- File management is provided by a journaling file system

- Local communication with the user via OLED display (4 lines / graphic) and 6-key keyboard

| Order num. | TXN 120 90.11NSNN |

|---|---|

| Teco code | TXN 120 90.11NSNN |

| Categories | Foxtrot 2 - Basic modules |

| Tags | - |

| System parameters of the central unit | |

|---|---|

| Row of central unit | I |

| User program memory | 1 MB |

| Memory for user variables / including RETAIN variables | 320 kB/48 kB |

| Instruction length | 4 Byte |

| Backup of program source code in PLC | Yes, optional in Mosaic |

| On-line program change in PLC | Yes, including I / O configuration change |

| DataBox - additional internal data memory | 128/257 kB, optional |

| File system - Internal Drive in PLC | 128 MB, journaling file system |

| File system - RAM disk PLC | 16 MB |

| File System - USB Flash Drive | Supported |

| File system - Micro SD card | supported (except for variants with WLAN1) |

| Optional memory card slot | microSD - Card Slot (<= 1TB) |

| Cycle time per 1k of logic instructions | 0,036 ms |

| Cycle time for 1k integer operations | 0,044 ms |

| Cycle time for 1k floating point operations | 0,043 ms |

| Development environment | Mosaic v2018.2 or higher |

| Programming languages | ST, IL, LD, FBD, SFC, CFC |

| RTC - Real time circuit | No |

| RTC - Backup time | typ. 500 hours |

| Integrated Web server | Yes |

| Integrated Datalogger | Yes |

| Access to PLC variables via web API | Yes |

| COM - Communication - IP/Ethernet | |

| Ethernet 10/100 Mb (ETHx) | 2 |

| WLAN1 (internal, optional) | 1 |

| WLAN2 (external via USB host, optional) | 1 |

| LTE interface (LTEx, optional) | 1 |

| Available system modes on ETH and WLAN | UNI, PC, PLC, PLD |

| TCP / IP protocol | Yes |

| UDP protocol | Yes |

| HTTPS protocol | Yes |

| HTTP protocol | Yes |

| WebSocket protocol | Yes |

| Protocol MODBUS/TCP | Yes |

| SMTP protocol | Yes |

| IEC 60870-5-104 protocol | Yes |

| REST API | Yes |

| COM - USB | |

| USB devices interface | 1x micro-USB |

| USB host interface | 1x USB-A |

| Available system modes on USB | PC |

| COM - Serial channels | |

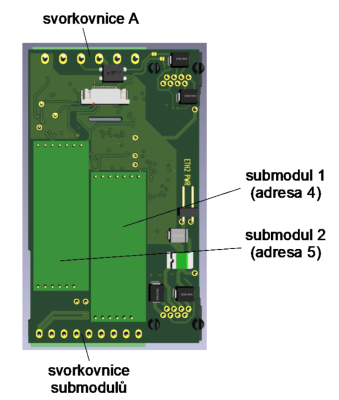

| max. number of optional serial channels in the basic module | 4 |

| number of slots for optional submodules with interface (MR-013x) | 2 |

| max. number of expanding serial channels on the TCL2 bus | 6 |

| Available system modes on CH5-10 | UNI, CSJ (CAN) |

| Modbus RTU / ASCII master protocol | Yes |

| Modbus protocol RTU/ASCII slave | Yes |

| Profibus DP master protocol (<180 kbit/s) | No |

| COM - System buses | |

| TCL2 - system I/O bus | 1x TCL2 master |

| TCL2 - Range of one branch of the system I/O bus | 10 I / O modules + 4 operator panels + 6 serial channels |

| CIB - Common Installation Bus (R): Installation I/O bus | 1x CIB master (100 mA) |

| CIB - Address range of one branch of the installation bus | 32 CFox I/O modules |

| Power supply | |

| Supply voltage, tolerances | 24 V DC, +25%, -15%, SELV |

| Maximum power input | 10 W |

| Module thermal/power loss | 8 W |

| Internal protection | Yes, PTC reversible fuse |

| CIB branch power supply - parameters of the built-in master | 1x 100 mA/ 24 V DC |

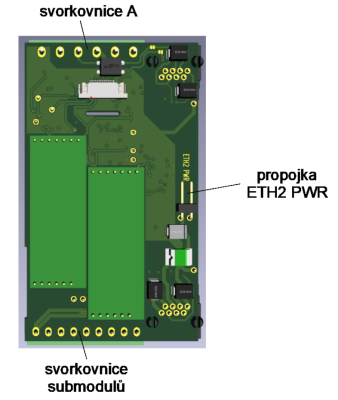

| Power supply from ETH, passive PoE - input (appliance) | ETH1/Power In |

| Power supply from ETH, passive PoE - output (source) | ETH2 / Power out, jumper configuration |

| Power supply from ETH, passive PoE - injector parameters | 24 V DC, 1A |

| Size and weight | |

| Weight approx. | 100 g |

| Product dimensions (width x height x depth) | 52 x 90 x 62 mm |

| Module width in multiples of M (17.5 mm) | 3M |

| Operating conditions, product standards | |

| Product standard | ČSN EN 61131-2:2008 (idt IEC 61131-2:2007) - Programmable control units |

| Protection class of electrical object | II, according to ČSN EN 61140 ed.3: 2016 (idt IEC 61140:2016) |

| IP rating (Ingress Protection) according to ČSN EN 60529: 1993 (idt IEC 529: 1989) | IP20 |

| Operating areas | Normal, acc. ČSN 33 2000-1 ed.2: 2009 (mod IEC 60354-1:2005) |

| Degree of pollution | 1, according to ČSN EN 60664-1 ed.2:2008 ( idt IEC 60664-1:2007) |

| Overvoltage category installation | II, according to EN 60664-1 ed_2: 2008 (idt IEC 60641-1: 2007) |

| Type of device | Module on DIN rail |

| Working position | Vertical |

| Type of operation (operating frequency) | Continuous |

| Ambient operating temperatures | -20 °C to + 55 °C |

| Operating temperature maximum (° C) | +55°C |

| Operating temperature minimum (° C) | -20°C |

| Operating relative humidity | from 10 % up to 95 % without condensation |

| Operating atmospheric pressure | min. 70 kPa (<3,000 m above sea level) |

| Storage temperatures | –25 °C to +70 °C |

| Electromagnetic compatibility, Mechanical endurance | |

| Electromagnetic compatibility / Emission | B, according to EN 55032 ed. 2: 2017 (idt CISPR 32: 2015) |

| Emmisions - note | In premises where the use of radio and television receivers can be expected to be used a distance of 10 m from these devices may cause radio interference. In such a case, the user may be required to take appropriate action. |

| Electromagnetic compatibility / Immunity | min. as required by EN 61131-2: 2007 |

| Sinusoidal vibration endurance | 10 Hz to 57 Hz, amplitude 0,075 mm, 57 Hz to 150 Hz, acceleration 1 G (Fc test according to EN 60068-2-6: 1997 (idt IEC 68-2-6: 1995), 10 cycles per axis.) |

| Packaginng, transportation, storage | |

| Description | The module is packed in a paper box according to the internal packing instructions. The package includes the following documentation. The outer packaging is carried out according to the scope of the order and the method of transport to the transport a package bearing the transport labels and other particulars necessary for transport. Transport from the manufacturer is carried out in the manner agreed upon when ordering. Product transport the customer's own means must be carried out by covered means of transport, in the specified position label on the packaging. The box must be stowed so as to prevent spontaneous movement a damage to the outer packaging. The product must not be exposed to direct weathering during transport and storage influences. Transport is allowed at temperatures from -25 ° C to +70 ° C, relative humidity 10% up to 95% (non-condensing) and a minimum atmospheric pressure of more than 70 kPa. Storage of the product is only allowed in clean rooms without conductive dust, aggressive gases and vapors. The most suitable storage temperature is 20 ° C |

| Installation | |

| Assembly description | Switchboard mounting |

| Assembly description | The basic module is mounted vertically on the U-rail ČSN EN 50022. The installation of the assembly (basic module and peripheral modules, if applicable) is performed according to TXV 004 50. |

| Exchangeable submodules | The optional MR-013x submodules of the serial interface are mounted in the base module CP-2007 on the bottom plate, which is accessible after removing the bottom of the housing. We only handle the module without power supply! |

| Connection | |

| Connection of power and system communication | connector with 2.5 mm2 screw terminal |

| Connection of inputs / outputs | connector with screw terminal 2.5 mm2 |

| Ethernet | RJ-45 |

| Serial channels | screw-type connector 9x 1.5 mm2 |

| USB device connection | type micro B |

| USB host connection | type A |

| Module operation | |

| Module configuration | The module is operated, set and diagnosed from the MOSAIC programming environment. It is also possible to connect to the PLC using a web browser on port 8080. If the PLC has an IP address set eg 192.168.134.178 (default address on port ETH1, port ETH2 has DHCP enabled), just enter the address in the form http://192.168.134.178:8080 and the web browser displays the PLC configuration pages. |

| Commissioning | The module is ready for operation after connection of the supply voltage. The MODE button is available on the module panel to display the currently set IP address of the Ethernet interface. Parameters of all interfaces are set in the Mosaic programming environment. The exact setup procedure is given in the TXV 004 50 documentation. |

| Module diagnostics | The basic diagnostic system of the module is part of its standard software. It operates from module power on and operates independently of the user. Diagnostic error states of the module and connected peripheral modules of the assembly are signaled on the module display and are available for processing by the master system. For more information, see TXV 004 50. |

| Maintenance | |

| Description | The module does not require any maintenance under general installation conditions. |

| Notice | Because the module contains semiconductor components, it is necessary to follow the principles for working with electrostatic sensitive components when handling the removed cover. It is not allowed to directly touch the printed circuit boards without protective measures !!! |

| Warranty | |

| Generally | Warranty and complaint conditions are governed by the Terms and Conditions of Teco a.s. |

| Notice | You must meet all the conditions of this documentation before turning on the system. The system must not be put into service unless it has been verified and confirmed that the machinery meets the requirements of Directive 89/392 / EEC, in so far as it applies to it. Documentation subject to change. |

HW documentation

CP-2090 - Basic documentation (en)

1.92 MB, (EN)

User manuals

CP-2090 - User's Guide (en), TXV00453_02

1.48 MB, (EN, RU, DE)

Foxtrot 2 - Serial communication (en)

2.25 MB, (EN, RU, DE)

Files for designers

Foxtrot 2 - library of elements in DXF and DWG formats, v. 2025/08.

21.80 MB

Foxtrot 2 - element library for SchemataCAD, v. 2025/08.

6.96 MB

EC - Declaration of Conformity

Foxtrot 2 - EC Declaration of conformity (en)

590.59 kB, (EN, RU, DE, UA)

- CP-2090 - The basic module CP-2090 is the basic module of the Foxtrot second generation control system. It is in standard version on DIN rail, in 3M cover (for dimensions of box see chapter 3M mechanika na DIN lištu ), it is equipped with six removable termi...

- Power dissipation of modules for calculation of switchboard heating - ...TXN 120 80.11NSNN CP-2080 CP-2080 9,0 W TXN 120 90.11NSNN CP-2090, CPU/1core, 2xETH100/10, ---, 128kB databox, LCD-7mm, CH1-4, 1xCIB, 1x TCL2 CP-2090, 8,0 W...

- Foxtrot 2 with LTE modem - The basic Foxtrot 2 modules, in addition to the smallest CP-2090, are also available with an internal LTE modem. The designation of the control panel is then eg CP-2005.11NSLN (TXN 120 05-11NSLN), where the letter L means LTE - see the tabl...

- Foxtrot 2 - Shifts to two! - ... And now in more detail to the individual news. Let's start with the ones that are visible. CP-2090; The smallest Foxtrot 2 has a half size The CP-2090 version is "brushed off" its integrated inputs and outputs,...

- Analog Input Module Capacity for Foxtrot 2 PLC - ...causing delays in reading values? Additionally, is it possible to read 160 analog inputs using a external TCL2 card on the CP-2090 module without any considerable delay in reading them?...

- How to Establish Communication Between Two PLCs - How can two PLCs communicate with each other? For example, I have two cp-2090, and I want to access a variable from the second PLC in a program on the first PLC. How can I achieve this?(using PLD)

- Analog Input Module Capacity for Foxtrot 2 PLC - ...log module IT-1604 is equipped with 8 analog inputs, for 160 analog inputs you will need 2 fully occupied TCL2 buses. One on CP-2090 interface, second one on an additional SE-0140 sub-module inserted to CP-2090's slot. These modules have multiple...