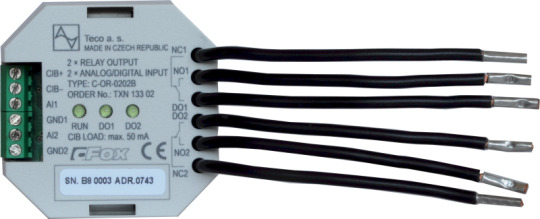

C-OR-0202BTXN 133 02

C-OR-0202B; CIB, 2x AI/DI; 2x RO NO/NC contacts; 230VAC/16A

| DI | |

|---|---|

| DI/AI | 2x DI/AI |

| DO | 2x RO 16A, NO / NC |

| AI | |

| AO | |

| COM | 1x CIB slave |

| SENSOR |

| Picture | Variant | Variant description |

|---|---|---|

|

C-OR-0202B |

C-OR-0202M is a module on the CIB bus that it contains

2 relay outputs with changeover contact 16A NO/NC, each separately connected to the terminal board

2 analog / binary inputs for connecting temperature sensors or potential-free contacts.

It is mounted in any position in the installation box under the lid or under the device in the installation box.

It is powered from the CIB bus

2 relay outputs with changeover contact 16A NO/NC, each separately connected to the terminal board

2 analog / binary inputs for connecting temperature sensors or potential-free contacts.

It is mounted in any position in the installation box under the lid or under the device in the installation box.

It is powered from the CIB bus

| Order num. | TXN 133 02 |

|---|---|

| Teco code | TXN 133 02 |

| Categories | CFox - Built-in modules |

| Tags | - |

| COM - System buses | |

|---|---|

| CIB - Common Installation Bus (R): Installation I/O bus | 1x CIB slave |

| DO/RO - Organization of binary outputs | |

| Total number of binary outputs | 2 |

| Number of binary output groups | 2 |

| RO - Parameters of binary relay outputs (group A) | |

| Parameters valid for the terminals | DO1, DO2 |

| Number of relay outputs | 2 |

| Number of output groups | 2 |

| Number of outputs in group | 1 |

| Organization of relay outputs into groups | 1x (D01) + 1x (DO2) |

| Output type | electromechanical relay, unprotected output |

| Contact type | NO / NC changeover contact |

| Galvanic separation from internal circuits | Yes |

| Galvanic isolation between groups | Yes |

| Diagnose | Alarm signaling on panel module |

| Switching current | 16 A max. NO/10 A max NC, 100 mA min. |

| Switching voltage | 300 V max., 5 V min. |

| Switching power | 4000 VA max., 384 W max. |

| Short-term output overload - inrush | 80 A max. (20 ms max.) |

| Contact closing time | typ. 15 ms |

| Contact opening time | typ. 5ms |

| Mechanical life | min. 20 000 000 cycles |

| Electrical life at rated load | min. 10,000 switchings (inrush 80 A) |

| Electrical life at maximum resistive load | min. 50,000 cycles |

| Short-circuit protection | No |

| Treatment of inductive load | External RC element, varistor (AC), diode (DC) |

| Insulation voltage between outputs and internal circuits | 4000 V AC |

| Isolation voltage between groups of outputs to each other | work isolation |

| Insulation voltage between contacts | 1000 V AC |

| AI - Organization of analog inputs | |

| Total number of analog inputs | 2 |

| Number of inputs per group | 1 |

| Number of analog input groups | 2 |

| Organization of analog inputs into groups | 1x (AI1) + 1x (AI2) |

| Input type | With common clamp |

| Common wire | GND terminal |

| Galvanic separation from internal circuits | No |

| Diagnostics | overload signaling in status word |

| Digital resolution | 10 bit |

| AI - Analog Input Ranges (Group A) | |

| Parameters valid for inputs on the terminals | AI1, AI2 |

| Passive sensor | Pt1000, W100 = 1,385 (-90 to +320 °C) |

| Passive sensor | Pt1000, W100 = 1,391 (-90 to +320 °C) |

| Passive sensor | Ni1000, W100 = 1,500 (–60 to +200 ° C) |

| Passive sensor | Ni1000, W100 = 1.617 (-60 to +200 ° C) |

| Passive sensor | Resistance transmitter 0-160 kOhm |

| Passive sensor | KTY81-121; PTC thermistor (-55 to + 125 °C) |

| Passive sensor | NTC Thermistor 12k / 25 °C (-40 to + 125 °C) |

| DI: Voltage-free contact | 0 when> 1.5 kOhm, 1 when <0.5 kOhm |

| DI: Balanced resistance input | 2x 1k1 (tamper/0/1/tamper) |

| Resistance measurement error - maximum error at 25 ° C | ± 0.5% of full scale |

| Power supply | |

| Supply voltage, tolerances | 24/27 V DC from CIB bus |

| Maximum power input | 1,5 W |

| Power supply from CIB - maximum current consumption (mA) | 50 mA |

| Galvanic separation of power supply from internal circuits | No |

| Power supply from CIB - Galvanic separation of power supply from internal circuits | No |

| Power supply from CIB - internal protection | Yes, returnable fuse |

| Size and weight | |

| Weight approx. | 75 g |

| Product dimensions (width x height x depth) | 50 x 50 x 30 mm |

| Operating conditions, product standards | |

| Product standard | ČSN EN 60730-1 ed. 2:2001 (mod IEC 60730-1:1999) |

| Protection class of electrical object | III, according to ČSN EN 61140 ed.3: 2016 (idt IEC 61140:2016) |

| IP rating (Ingress Protection) according to ČSN EN 60529: 1993 (idt IEC 529: 1989) | IP20 |

| Operating areas | Normal according to ČSN 33 2000-1: 2003 (IEC 364-1: 1992 mod) |

| Degree of pollution | 1, according to ČSN EN 60664-1 ed.2:2008 ( idt IEC 60664-1:2007) |

| Overvoltage category installation | I, according to ČSN EN 60664-1 ed_2:2008 (idt IEC 60641-1:2007) |

| Type of device | In the installation box, under the cover |

| Working position | Any |

| Type of operation (operating frequency) | Continuous |

| Ambient operating temperatures | -10 °C to + 55 °C |

| Operating temperature maximum (° C) | +55°C |

| Operating temperature minimum (° C) | -10°C |

| Operating relative humidity | from 10 % up to 95 % without condensation |

| Operating atmospheric pressure | min. 70 kPa (<3,000 m above sea level) |

| Storage temperatures | –25 °C to +70 °C |

| Electromagnetic compatibility, Mechanical endurance | |

| Electromagnetic compatibility / Emission | B, according to EN 55022: 1999 (mod CISPR22: 1997) |

| Emmisions - note | In premises where the use of radio and television receivers can be expected to be used a distance of 10 m from these devices may cause radio interference. In such a case, the user may be required to take appropriate action. |

| Electromagnetic compatibility / Immunity | min. according to ČSN EN 60730-1 ed.2: 2001 |

| Sinusoidal vibration endurance | 10 Hz to 57 Hz, amplitude 0,075 mm, 57 Hz to 150 Hz, acceleration 1 G (Fc test according to EN 60068-2-6: 1997 (idt IEC 68-2-6: 1995), 10 cycles per axis.) |

| Packaginng, transportation, storage | |

| Description | The module is packed in a paper box. This documentation is also part of the package. The outer packaging is carried out according to the scope of the order and the method of transport in a transport package provided with labels and other data necessary for transport. The product must not be exposed to direct weather conditions during transport and storage. Malting of the product is only allowed in clean rooms without conductive dust, aggressive gases and vapors. The most suitable storage temperature is 20 ° C |

| Installation | |

| Assembly description | The module is mounted in a vertical position on the U-rail ČSN EN 50022. Installation of the assembly (basic module and possibly peripheral modules) is performed according to TXV 004 13. |

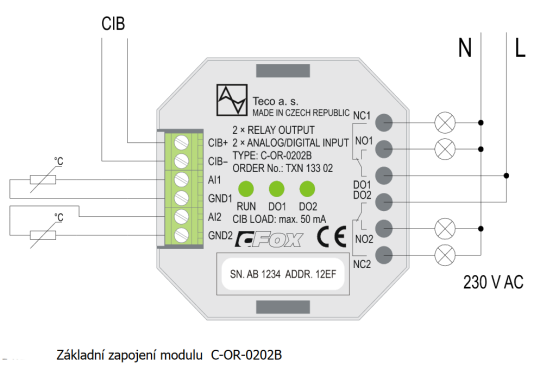

| Connection | |

| Connection of power and system communication | terminal block with screw terminal 1.5 mm2 |

| Specific I / O | Relay outputs |

| Connection of specific I / O | Insulated wires with sleeve |

| Cross-section of connected wires stranded (max) | 2,5 mm2 |

| Module installation tools | (-) 3 mm, flat screwdriver |

| Module connection |

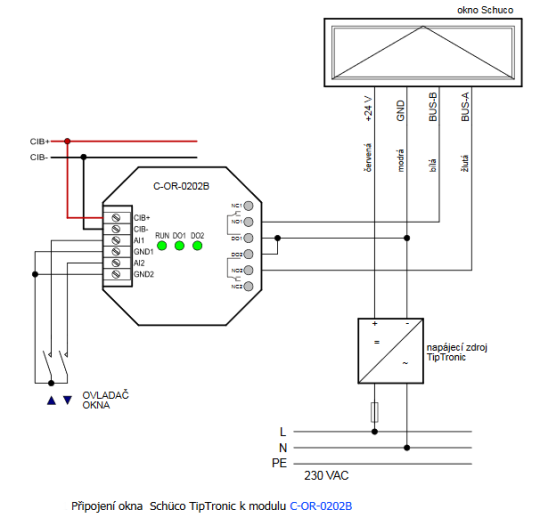

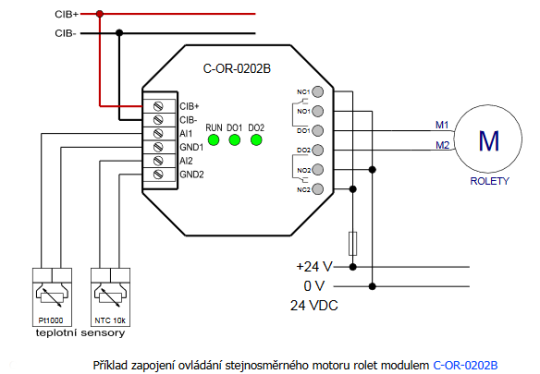

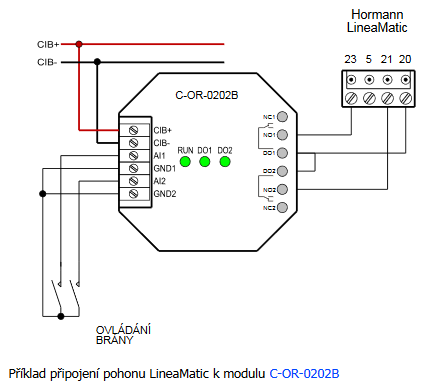

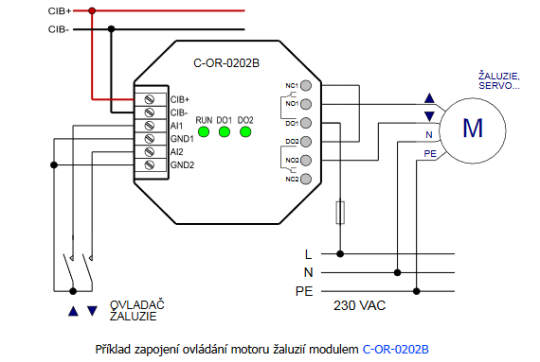

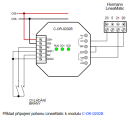

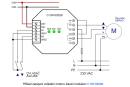

The module has a CIB bus and 2 inputs are connected to screw terminals, the changeover contacts of the relay are connected by means of insulated conductors with a length of approx. 80 mm terminated in sockets. The CIB bus master is a FOXTROT base unit or module, such as the CF-1141. The maximum number of modules on a line is limited by taking a module from the line. For more information, see the Peripheral Modules on the CIB TXV 004 13 manual. An example of the module connection is shown in the following figure. |

| Module operation | |

| Commissioning | The module is operated, set and diagnosed from the MOSAIC programming environment or other parameterization software. The module is ready for operation after connecting the supply voltage and the CIB bus. The HW address is indicated on the label on the module. |

| Module diagnostics | The basic diagnostics is performed internally and the result is available in the relevant registers of the Mosaic environment. When the power is turned on, the RUN LED lights up green, after communication is established, it starts flashing. The switching status of the relay is indicated by a green LED. |

| Maintenance | |

| Description | The module does not require any maintenance under general installation conditions. The operations in which a part of the module has to be dismantled must always be carried out with the supply voltage disconnected. |

| Notice | Because the module contains semiconductor components, it is necessary to follow the principles for working with electrostatic sensitive components when handling the removed cover. It is not allowed to directly touch the printed circuit boards without protective measures !!! |

| Warranty | |

| Generally | Warranty and complaint conditions are governed by the Terms and Conditions of Teco a.s. |

| Notice | You must meet all the conditions of this documentation before turning on the system. The system must not be put into service unless it has been verified and confirmed that the machinery meets the requirements of Directive 89/392 / EEC, in so far as it applies to it. Documentation subject to change. |

HW documentation

C-OR-0202B - Basic documentation

990.05 kB, (EN)

User manuals

Peripheral module on CIB-Common Installation Bus(R) (cs), TXV00413_01

14.01 MB

Peripheral modules on the CIB Common Installation Bus(R) (en), TXV00413_02

13.94 MB, (EN, RU, DE, UA)

Files for designers

Foxtrot 2 - library of elements in DXF and DWG formats, v. 2025/08.

21.80 MB

Foxtrot 2 - element library for SchemataCAD, v. 2025/08.

6.96 MB

EC - Declaration of Conformity

Foxtrot - EC Declaration of conformity

295.20 kB, (EN, RU, DE, UA)

- Control of asynchronous motors for blinds, awnings, C-OR-0202B - ...hielding element in the installation box. Fig.1 Example of connection of blind motor control by module C-OR-0202B Notes: Relay outputs with mutual blocking of switching of both outputs, when DO1 is closed the mo...

- C-OR-0202B, relay outputs and analogue inputs - The C-OR-0202B module is equipped with 2 relays with a switching contact, each is separately terminated with insulated conductors, their length is approx. 100mm. Continuous current in each 16 A output, switching inrush current up to 80A (maximum 20...

- 16 A relay (80 A switching current), the CFox and RFox peripheral modules_kopie464 - These relays are fitted in e.g. the C-OR-0008M , C-OR-0202B , R-OR-0001B peripheral modules, and others (see the information on the individual modules ). The NO contact is designed as increased (inrush current 80 A), the NC con...

- Electric underfloor heating - ...relay outputs in accordance with the switching power. You can make use of the relay output directly to the flush box ( C-OR-0202B with a possibility of simultaneously measuring the floor temperature), or the C-OR-0008M module, which ca...

- 16 A relay (80 A switching current), the CFox and RFox peripheral modules - These relays are fitted in e.g. the C-OR-0008M , C-OR-0202B , R-OR-0001B peripheral modules, and others (see the information on the individual modules ). The NO contact is designed as increased (inrush current 80 A), the NC con...

- The control of Schüco windows - ...n be used for the control; it is appropriate to use two separate, mutually independent outputs - see the example with the C-OR-0202B module. Fig. 1. Connecting a Schüco TipTronic window to the C-OR-0202B module N...

- Connecting the LineaMatic sliding gate - ...partial opening of the gate (about 1.5m) for the passage of people. To control the gate it is recommended to use the C-OR-0202B module located at the gate. The module inputs can be used e.g. for the local control buttons, or for connecting...

- Control of direct current motors for roller blinds - ...tage (motors for interior blinds, and such like), we recommend to use relay outputs with a switching contact, such as the C-OR-0202B . Fig. 1. An example of wiring the control of DC motor for roller blinds by the C-OR-0202B module...

- Control of socket circuits and sockets - ...puts of the C-HM-1121M module and their RFox variants), see this article placed in the installation box C-OR-0202B and R-OR-0001B , see this article For switching 3f sockets, usually with a higher rated...

- Switching of LED lighting, light bulbs, fluorescent lamps, etc. - ...ith short-term switching current up to 80 A C-OR-0008M 8 relay outputs with short-term switching current up to 80 A C-OR-0202B 2 relay outputs with short-term switching current up to 80 A C-HM-1113M 1 relay output with short-term switc...

- Valves for controlling water (the main water valve, etc.) - The valve designed to control the distribution of drinking water (e.g. the main water valve), automatic control of irrigation systems, etc. Its design is also suitable for the so-called hard water. It is a good replacement of solenoids and pneumatic...

No data available.