UC-1204TXN 112 04

UC-1204; Open Therm, communication module for boiler connection

| DI | |

|---|---|

| DI/AI | |

| DO | |

| AI | |

| AO | |

| COM | 1x OpenTherm 1x TCL2 slave |

| SENSOR |

| Picture | Variant | Variant description |

|---|---|---|

|

UC-1204 |

UC-1204; Open Therm

The UC-1204 module is used to connect a device (boiler) communicating with the bidirectional OpenTherm protocol to the TECOMAT FOXTROT PLC. The module is designed for "point-to-point" connection, ie. allows you to connect one OpenTherm device. The UC-1204 module acts as a master (control unit) in OpenTherm communication, so the connected device must be of the slave type. The module supports devices according to the complete OpenTherm specification (v.2.2) called OpenTherm Plus (OT / +) and according to the basic specification called OpenTherm Lite (OT / -).

The UC-1204 module is used to connect a device (boiler) communicating with the bidirectional OpenTherm protocol to the TECOMAT FOXTROT PLC. The module is designed for "point-to-point" connection, ie. allows you to connect one OpenTherm device. The UC-1204 module acts as a master (control unit) in OpenTherm communication, so the connected device must be of the slave type. The module supports devices according to the complete OpenTherm specification (v.2.2) called OpenTherm Plus (OT / +) and according to the basic specification called OpenTherm Lite (OT / -).

| Order num. | TXN 112 04 |

|---|---|

| Teco code | TXN 112 04 |

| Categories | Foxtrot - Communication Modules (TCL2) |

| Tags | - |

| COM - Serial channels | |

|---|---|

| OpenTherm | Yes |

| COM - System buses | |

| TCL2 - system I/O bus | 1x TCL2 slave |

| Power supply | |

| Supply voltage, tolerances | 24 V DC, +25%, -15%, SELV |

| Typical power input | 0,25 W |

| Maximum power input | 0,4 W |

| Module thermal/power loss | 0,4 W |

| Galvanic separation of power supply from internal circuits | Yes |

| Internal protection | Yes, PTC reversible fuse |

| Size and weight | |

| Weight approx. | 50 g |

| Product dimensions (width x height x depth) | 18 x 90 x 58 mm |

| Module width in multiples of M (17.5 mm) | 1M |

| Operating conditions, product standards | |

| Product standard | ČSN EN 61131-2: 2005 (idt IEC61131-2: 2003) - Programmable control units |

| Protection class of electrical object | III, according to ČSN EN 61140 ed.3: 2016 (idt IEC 61140:2016) |

| IP rating (Ingress Protection) according to ČSN EN 60529: 1993 (idt IEC 529: 1989) | IP20 |

| Operating areas | Normal, acc. ČSN 33 2000-1 ed.2: 2009 (mod IEC 60354-1:2005) |

| Degree of pollution | 1, according to ČSN EN 60664-1 ed.2:2008 ( idt IEC 60664-1:2007) |

| Overvoltage category installation | II, according to EN 60664-1 ed_2: 2008 (idt IEC 60641-1: 2007) |

| Type of device | Module on DIN rail |

| Working position | Vertical |

| Type of operation (operating frequency) | Continuous |

| Ambient operating temperatures | 0 ° C to + 55 ° C |

| Operating relative humidity | from 10 % up to 95 % without condensation |

| Operating atmospheric pressure | min. 70 kPa (<3,000 m above sea level) |

| Storage temperatures | –25 °C to +70 °C |

| Electromagnetic compatibility, Mechanical endurance | |

| Electromagnetic compatibility / Emission | A, according to EN 55022: 1999 (mod CISPR22: 1997) |

| Emmisions - note | In premises where the use of radio and television receivers can be expected to be used a distance of 10 m from these devices may cause radio interference. In such a case, the user may be required to take appropriate action. |

| Electromagnetic compatibility / Immunity | min. as required by EN 61131-2: 2007 |

| Sinusoidal vibration endurance | 10 Hz to 57 Hz, amplitude 0,075 mm, 57 Hz to 150 Hz, acceleration 1 G (Fc test according to EN 60068-2-6: 1997 (idt IEC 68-2-6: 1995), 10 cycles per axis.) |

| Packaginng, transportation, storage | |

| Description | The module is packed in a paper box. This documentation is also part of the package. The outer packaging is carried out according to the scope of the order and the method of transport in a transport package provided with labels and other data necessary for transport. The product must not be exposed to direct weather conditions during transport and storage. Malting of the product is only allowed in clean rooms without conductive dust, aggressive gases and vapors. The most suitable storage temperature is 20 ° C |

| Connection | |

| Connection of power and system communication | connector with 2.5 mm2 screw terminal |

| Module operation | |

| Module configuration | The module is operated, set up and diagnosed from the Mosaic development environment. |

| Module diagnostics | The basic diagnostic system of the module is a part of its standard software. It operates from module power on and operates independently of the user. Diagnostic error states of the module and connected peripheral modules of the assembly are signaled |

| Module diagnostics |

There are two indicator LEDs on the front panel of the module, marked RUN and OT. If the green RUN LED is lit, the module is in HALT mode (does not operate the connected device), if the RUN LED flashes, the module is in RUN mode (operates the connected device). If the OT LED flashes green, it signals operation on the OpenTherm bus in OpenTherm Plus mode, if it is permanently lit, it signals operation on the bus in OpenTherm Lite mode, when it is not lit, the module is not configured. |

| Maintenance | |

| Description | The module does not require any maintenance under general installation conditions. The operations in which a part of the module has to be dismantled must always be carried out with the supply voltage disconnected. |

| Notice | Because the module contains semiconductor components, it is necessary to follow the principles for working with electrostatic sensitive components when handling the removed cover. It is not allowed to directly touch the printed circuit boards without protective measures !!! |

| Warranty | |

| Generally | Warranty and complaint conditions are governed by the Terms and Conditions of Teco a.s. |

| Notice | You must meet all the conditions of this documentation before turning on the system. The system must not be put into service unless it has been verified and confirmed that the machinery meets the requirements of Directive 89/392 / EEC, in so far as it applies to it. Documentation subject to change. |

HW documentation

UC-1204 - Basic documentation

533.85 kB, (EN)

Files for designers

Foxtrot 2 - library of elements in DXF and DWG formats, v. 2025/08.

21.80 MB

Foxtrot 2 - element library for SchemataCAD, v. 2025/08.

6.96 MB

EC - Declaration of Conformity

Foxtrot - EC Declaration of conformity

295.20 kB, (EN, RU, DE, UA)

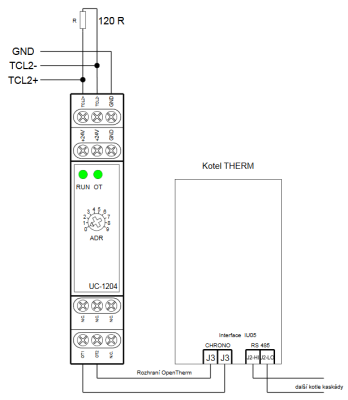

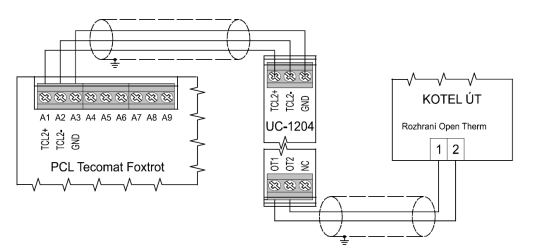

- UC-1204, communication with the boiler with the OpenTherm interface - The UC-1204 module is designed to connect the equipment (a boiler) communicating via a two-way protocol OpenTherm with the Foxtrot basic module. The module is designed for "point-to-point" connections, i.e. it allows to connect a single OpenT...

- Power dissipation of modules for calculation of switchboard heating - ...MP-bus, communication module for Belimo actuators UC-1203 2,5 W TXN 112 04 UC-1204; Open Therm, communication module for connecting boilers UC-1204 0,4 W TXN 1...

- The boiler – control and regulation of the central heating sources - ...eration of the heat pump. The boilers equipped with the OpenTherm interface can be controlled via the UC-1204 module. For an example of basic wiring and connection to the Thermona boiler fitted with the IU05 inte...

- Connecting Thermona boilers with the OpenTherm interface - ...e makes it possible to implement a boiler cascade via its own bus. Fig. 1 An example of connection of the UC-1204 module to a Thermona boiler (the IU05 interface)...

- UC-1203, a module for connecting the MP-Bus actuators - ...plastic 1M box (17.5 mm wide); the dimensions are listed in Chapter 13.2.4 . Tab. 1 Basic parameters of the UC-1204 module System bus TCL2 Su...

No data available.